NEWS CENTER

News center

Steel material environmental corrosion field table

- 分类:Company news

- 作者:

- 来源:

- Release time:2020-05-07

- Visits:3

【全国十大赌博官网】

Steel material environmental corrosion field table

【全国十大赌博官网】

- 分类:Company news

- 作者:

- 来源:

- Release time:2020-05-07

- Visits:3

|

摘要:介绍了国内外钢铁材料环境腐蚀试验技术发展的现状,总结了新型耐蚀钢铁材料研发中所需的各类试验方法,分析了室外暴露试验、室内模拟加速试验、在线腐蚀监检测与大数据评估技术的研究重点和发展趋势。鉴于钢铁材料自然环境腐蚀试验对保障其服役过程中的安全性和可靠性至关重要,构建规范化、标准化的环境腐蚀试验技术体系是提升我国钢铁材料品质的重要工作。

钢铁材料作为最重要的结构材料, 几乎遍及所有工业,随着能源工业、海洋资源及舰船工业的发展,对高性能结构耐蚀钢的需求越来越迫切。然而,在环境作用下钢铁材料会发生腐蚀,根据“我国腐蚀状况及控制战略研究” 重大咨询项目数据显示, 2014 年我国全行业腐蚀总成本约占国内生产总值( GDP )的 3.34% ,达到 2.13 trillion yuan, corrosion products and failed materials/products also cause serious pollution and far-reaching impact on the environment 。由于钢铁在大气、土壤和水等自然环境下的腐蚀数据具有不可引进、公益性、长期性和连续性的特点,因此,开展材料环境腐蚀科学数据积累与共享以及规范化、 标准化的环境腐蚀试验技术是提升我国钢铁材料品质极其重要的基础性工作 。

长期以来, 钢铁材料环境腐蚀研究的重点一直围绕着试验设备、技术、方法与标准展开。With the advent of the information age, Data science also plays an important role in corrosion test research,All kinds of natural environment corrosion tests under atmospheric, water, soil and microbial conditions,Or stress corrosion, pitting corrosion and galvanic corrosion and other types of local corrosion tests, Include the corrosion resistance of the component or equipment as a whole, Some data have been accumulated both at home and abroad, With the use of high throughput testing technology and means,Its data volume will grow rapidly。与此同时,数据挖掘、支持向量机、 贝叶斯模型等数据分析及建模方法也为腐蚀科学研究提供了有力支撑。这些数据以及数据分析方法对深入研究腐蚀机理、 长期跟踪腐蚀规律、发展新型耐蚀合金、确定腐蚀控制技术以及为工程设计选材都起到极其重要的作用。The demand for data and information research in corrosion science is the source of the generation and development of corrosion informatics 。

据此, This paper summarizes the environmental corrosion test technology of iron and steel materials and the current research situation abroad, To provide basic information for its further application in China,It provides reference for the design, research and manufacture of iron and steel materials, It provides a theoretical basis for the material selection of equipment serving in various environments, Improve the reliability and durability of steel products and equipment in China。

1 Natural environment exposure corrosion test technology

十八世纪中叶到二十一世纪, 人们对金属腐蚀的认识过程由经验性阶段过渡到系统性学科研究阶段。The research on environmental corrosion of modern materials has a history of nearly a hundred years,Take atmospheric corrosion as an example,The accumulation of metal corrosion data in outdoor natural environment began in 1906,By the American Society for Testing Materials (ASTM) to establish the atmospheric corrosion test website,Corrosion tests of various materials were carried out in atmospheric environment。20 世纪 20 年代英国的 Vernon 将金属试样表面清理干净后暴露在室外自然环境中,测定腐蚀速率,标定主要腐蚀产物。Vernon's experimental research method has been used until now, but the observation and characterization instruments have been substantially improved。由于Vernon 的试验研究,腐蚀学科才由所谓的“艺术”领域转入科学领域, 在大量自然环境腐蚀数据的基础上对金属在大气中的腐蚀机理进行了深入的研究 。

All countries in the world attach great importance to the study of environmental adaptability of steel and its products during production, transportation and service,Actively carry out corrosion data accumulation and experimental research of materials in typical natural environment,Master the corrosion laws of various materials in the natural environment,This is useful for controlling material environmental corrosion,It is of great significance to reduce economic losses。钢铁材料的自然环境适应性研究十分复杂,影响因素很多,难以在实验室进行模拟,必须通过野外试验站点的现场试验与观测,才能获得符合实际的环境适应性数据。材料自然环境试验站网的建设与数据积累工作已有上百年的历史,由于各国的自然环境条件各不相同,差别也很大。

Our country has a vast territory,Complex natural environment,It is distributed north-south in seven climatic zones,因此形成了 7 种典型大气环境(农村、城市、工业、海洋、高原、沙漠、热带雨林)、五大水系(黄河、长江、珠江、松花江和淮河)、 4 个海域(渤海、黄海、东海和南海)以及 40 多种土壤类型。

The corrosion rate of materials in different environments can be several times or even tens of times, and it is impossible to simply replace the data of developed countries。只有通过长期数据积累和实验研究, 才能掌握本国自然环境条件下材料的腐蚀数据和规律。

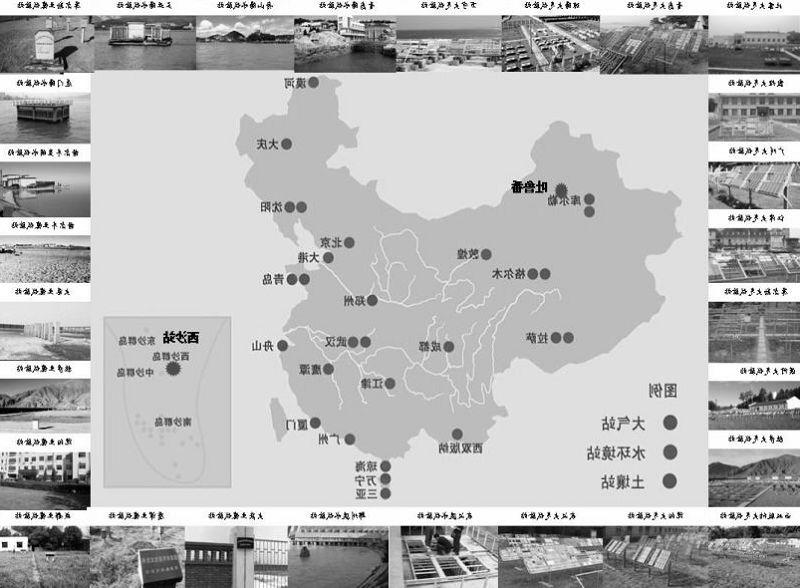

China's natural environment corrosion test began in the 1950s,After decades of construction and development,According to the basic conditions of China's material environment corrosion station, Establish national field station planning with the Ministry of Science and Technology,Coordinate more than ten units across industries, departments and regions,A national material environmental corrosion platform consisting of 31 field test stations and 1 center has been jointly built,见图 1 。该平台包括 16个大气腐蚀、 8 个土壤腐蚀和 7 个水腐蚀试验站,西起库尔勒,东到舟山岛,北起漠河,南至西沙,覆盖了我国所有典型自然环境区带。建设了野外环境腐蚀试验场地, 制定了成套环境腐蚀试验规程与技术,这些环境腐蚀试验规程已形成为 28 项腐蚀行业标准;建立了材料环境腐蚀信息资源共享十大网赌正规平台 - 中国腐蚀与防护网 ( www.ecorr.org ), for all sectors of society, to provide material corrosion (aging) physical resources and information resources services 。

Figure 1. Distribution of national material environmental corrosion platform system test stations

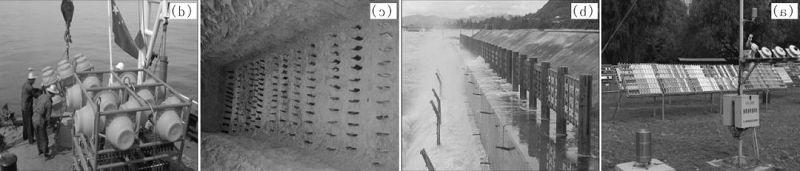

室外环境暴露试验是自然环境试验中最常用的试验方法,按照暴露方式可以分为直接暴露、半封闭暴露和全封闭暴露三种。对暴露场址的选择主要应结合各种环境因素对钢铁产品的作用及其效果,试验结果的代表性和准确性,性能变化及速度等方面综合考虑。国内现有自然环境腐蚀试验站已能代表我国典型自然环境区域类型, 通过研究环境因素对钢铁材料腐蚀的影响, 及不断的数据积累, 获得钢铁材料在国内典型环境中的腐蚀规律。在耐蚀钢铁研发和装备环境适应性评估中,我国已建立了满足国际标准的野外试验成套技术,并获得广泛应用。The National Material environmental corrosion platform has completed the largest material environmental corrosion test in China,Including carbon steel, weathering steel, stainless steel and coating more than 100 kinds of materials,According to the characteristics of China's vast territory and complex natural environment,Systematic exposure tests were conducted for 16 years,Modeling of atmospheric, soil and seawater corrosion by zoning and classification ,见图 2 。

( a ) 大气环境( b ) 水环境( c ) 土壤环境 ( d ) 深海环境

Figure 2 Natural corrosion test of steel in atmosphere, water, soil and deep sea environment

With the implementation of the national "One Belt, One Road" strategy,国家材料环境腐蚀平台从 2015 年开始便在东南亚地区开展了钢铁材料环境腐蚀试验和数据积累,Natural environment corrosion tests were carried out in Thailand, Indonesia, Singapore, Malaysia and other places,These efforts will guide the construction and application demonstration of major projects such as port material selection, ocean engineering and high-speed railways。

在材料环境腐蚀观测试验研究全球化的趋势下,为了提高材料对环境的适应性,以及对环境腐蚀性的可比性, 以积累材料腐蚀数据为主要目的观测试验研究工作, 从暴露方法到检测手段都采用统一的规范和标准。In developed countries, the standardization development of environmental corrosion observation test of materials has been widely paid attention to。近年来,美国、日本、德国及北约其他国家在材料环境腐蚀方面投入大量的人力、物力,进行大量试验研究和数据积累, 积极推进材料环境腐蚀观测试验标准化进程。国际上以 ISO 为代表的标准化组织也建立了较为成熟和完善的材料腐蚀观测试验标准化体系, 目前经公开出版的标准已达到 60 多项。The United States and other developed countries have established a detailed material environmental corrosion test standardization system suitable for their national conditions。Take the United States,美国国家标准局、材料试验协会( ASTM )、腐蚀工程师学会( NACE )、金属学会( ASM )和美国石油学会( SPI )等组织共研究制订了上千项材料腐蚀与防护标准和规范,Formed a very specific and perfect standard system,There are more than 800 standards of atmospheric corrosion observation tests for materials that are being implemented。美国阿特拉斯( ATLAS )气候服务集团的材料环境腐蚀试验均按照 ASTM 、 SAE 、 MIL 、 DIN 、JIS 、 Nissan 等标准进行观测研究。因此,在自然环境暴露试验研究中,通过科学、系统的管理和各类标准体系的建立与运行, 进一步提高钢铁材料及其制品环境腐蚀数据的权威性和科学性。

2 Indoor environment accelerated corrosion test technology

在自然环境中, 由于钢铁材料失效评价的周期很长,现场试验影响因素复杂多变,完全采用现场试验方法无法满足钢铁材料新产品研发和材料腐蚀寿命评估与预测的需求。因此,必须建立钢铁材料加速腐蚀试验技术, 以预测实际环境下钢铁及其构件的长期服役行为和使用寿命。

国内外普遍认为室内环境加速腐蚀试验不能简单代替自然环境腐蚀暴露试验,实验室加速腐蚀试验的评价标准依赖于室内外腐蚀试验的相关性。

由于理论性强、环境多样、影响因素多、数据和案例积累不足,具有良好室内外相关性的加速腐蚀试验技术长期发展迟滞。因此,发展系列化材料环境加速腐蚀评价新理论和新技术具有重大实用价值和科学意义,也是钢铁材料环境试验技术研究中的重点之一。The development of simulated accelerated test technology for atmospheric, seawater and soil environment corrosion is introduced below。

The early indoor simulation and acceleration methods of atmospheric corrosion mainly used the wet heat test method, including SO2、 H2S, CO2The accelerated corrosion test of simulated corrosive gas was carried out。ASTM 在 1962 年制定了三种盐雾试验标准 , 即中性盐雾试验、醋酸盐雾试验和醋酸氯化铜盐雾试验。At present, salt spray test is still the most commonly used method for Marine atmospheric corrosion acceleration simulation test。但大量试验证明, 盐雾试验方法仅能作为一种人工加速腐蚀的试验方法, 并不能很好地对海洋等含氯离子的环境进行模拟。各种单一的盐雾试验对大气暴露的模拟性都不好,其主要原因是盐雾试验不具有“湿润 -干燥”循环过程,在自然大气条件下,试样上由雨、雾等形成的液膜有一个由厚变薄、 由湿变干的周期性循环过程。Therefore, some scholars have proposed a salt spray composite test method with periodic brine spray during drying process。日本学者在 1980 年提出一种周期浸润复合循环试验的方法, 这种加速模拟方法具有良好的再现性。Pourbaix 采用这种方法研究大气腐蚀, 通过周期性浸入蒸馏水、 NaHSO3或 NaCl 溶液,分别模拟加速乡村气氛、工业气氛和海洋气氛下的大气腐蚀情况,研究表明,几个星期的实验可与一年或更长时间的自然曝晒相匹配。

近年来,国外学者又将周期喷雾、周期浸润等试验综合起来,出现了多种环境因子循环复合腐蚀试验。Not only to achieve the temperature, relative humidity, dry and wet frequency, dry/wet alternations, pollutants SO2、 CO2含量和风速等环境因子的控制, 还可以模拟多种气象条件下的大气腐蚀,获得与真实大气暴露试验相近的数据。目前,国际上对模拟大气腐蚀加速试验的研究已从获得单一或几个环境因素向多因子复合加速腐蚀的方向发展。在进行加速试验研究时, 并不是对大气腐蚀现象的模拟,而是对大气腐蚀本质规律的模拟。多年来材料大气环境当量加速试验环境谱的研究一直受到国内外学术界和工程界的高度重视, In particular, developed countries are concerned about the influence of corrosive environment on the life of equipment such as aircraft structure, Life prediction method in corrosive environment, 结构的腐蚀控制以及结构模拟件试验室加速腐蚀试验技术及环境谱等方面进行了许多卓有成效的研究 。

The laboratory simulation accelerated experiment method was adopted, On the basis of a large amount of corrosion data accumulation, National Material Environmental corrosion platform comprehensive research center for site conditions,Especially Xisha high temperature, high humidity, high salt fog of the ocean atmosphere,The simulated solution conforming to Xisha atmospheric environment characteristics was determined,An accelerated laboratory test method for periodic infiltration + salt spray corrosion environment spectrum was designed,A series of atmospheric corrosion acceleration test devices such as periodic infiltration corrosion test chamber and micro-corrosive gas environment test chamber have been designed, Simple and fast electrochemical test device and electrolytic cell device that can automatically control thin liquid thickness, The research and testing technology of atmospheric corrosion mechanism, such as reference electrode, which is suitable for electrochemical testing of thin layer solution, has been developed。On the basis of atmospheric corrosion accelerated corrosion test series technology, 对大气室外暴露材料的实际情况、影响因素、灰色关联分析、环境谱编制和室内加速试验进行了系统研究,A set of systematic and reliable environmental spectrum accelerated test method and life evaluation theory system are established,It has been widely used in aviation, aerospace, electronics, automotive and other industries。

Marine environment is one of the harshest natural environments for material corrosion。Solid sea corrosion test is a reliable corrosion test method in Marine environment,But this kind of test is long and expensive,In order to obtain a large number of test data in a short time,A simulated accelerated test method and evaluation technique for Marine corrosion laboratory were developed,作者团队研制了一系列新型的海洋腐蚀室内模拟加速试验装置和深海环境腐蚀性能模拟加速试验装置,见图 3 ,The corrosion acceleration test of materials in shallow sea and deep sea environment was studied。

FIG. 3 Marine corrosion simulation accelerated test technology and a series of devices

海洋腐蚀室内模拟加速试验装置实现了干湿交替、不同腐蚀性气体环境控制及模拟不同海洋腐蚀区带(海洋大气区、飞溅区、潮差区、全浸区)的功能, Indoor simulation/accelerated corrosion tests and electrochemical tests can be performed simultaneously under multi-factor complex Marine environmental conditions,It is suitable for simulated accelerated corrosion test of various metal materials in Marine environment in laboratory。

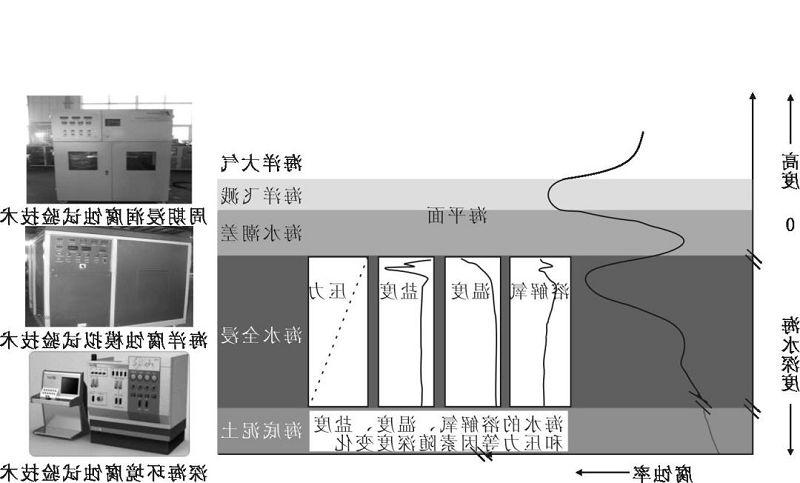

After verification, The simulated accelerated test device can simulate the multi-zone corrosion and erosion corrosion behavior of the ocean, The deep sea environment corrosion performance test device of the material in Figure 3, Control of physical and chemical parameters of seawater (e.g., dissolved oxygen, temperature, pressure, salinity, etc.) using flow circulation systems,The pressure can be increased to more than 50 MPa (pressure conversion only),Equivalent to 5 000 m deep sea)。该装置真实地模拟钢铁材料在实际深海环境中低温高压工况,解决现有深海试验获取实验数据时间长, 数据类型单一,以及静态高压釜不能真实模拟实际深海环境等的问题。使用该装置可以了解典型金属材料在模拟深海环境不同压力、介质等特征下的腐蚀行为,图 4 给出了 X70 管线钢在模拟不同深度海水环境下表面腐蚀行为 。

( a ) 0 m 表面 ( b ) 0 m 内层锈 ( c ) 860 m ( d ) 1 200 m

FIG. 4 Macroscopic morphologic photos of X70 steel U-bend specimen after soaking in different simulated depths

影响钢铁材料土壤腐蚀的环境因素复杂,利用短期加速腐蚀试验结果预测钢铁材料长期的腐蚀行为及使用寿命一直是环境腐蚀试验与评估技术的难点之一。目前,我国已研发出系列钢铁土壤腐蚀试验用装备与评价方法,开发了土壤腐蚀模拟加速试验箱,以及用于沟槽腐蚀敏感性测试和评价技术,这些方法及其相关标准已在工业界推广应用,促进了新型耐蚀高强管线钢的评价与研发。

国家材料环境腐蚀平台选择具有代表性的鹰潭土壤和库尔勒地区土壤为主要研究对象, 另选国内其它 6 种典型地区的土壤作为对比, 对钢质管道在典型土壤环境中的腐蚀类型进行分析。Through the corrosion data analysis of Q235 steel, X70 steel ~ X120 steel and other materials,The evaluation indexes of soil corrosivity were established and screened from three perspectives: uniform corrosion, pitting corrosion and stress corrosion,The gray correlation model is applied, Combined with genetic algorithm and other data correlation analysis methods,遴选出土壤电阻率、含水量、土壤 pH 值、土壤质地、氧化还原电位、管地电位、含盐量和 Cl-含量等作为土壤腐蚀性关键环境参数,进而建立了基于这 8 项土壤性质指标的“埋地钢质管道土壤腐蚀性综合评价方法”。Through the verification of existing data from 8 national soil stations, the above method is highly consistent with the actual data。With foreign methods (DIN-50929 and ANSI A21.5 )相比,该方法不仅采用了国际通用的多指标土壤腐蚀性评价方法, 还弥补了国际主流标准中土壤腐蚀性评价方法实用性差的不足, 提高了多指标土壤腐蚀性综合评价方法的实用性和评估的准确性 。

3. Online corrosion monitoring and big data evaluation technology

随着信息技术的发展,美国于 2011 年提出“材料基因组计划”, 数据共享与计算工具开发的理念与材料腐蚀平台始终坚持数据共享工作,以及不断发展模拟计算研究非常契合。Materials Corrosion Informatics and related work published in 2014,The goal of the Materials Genome Project is to reduce the current materials development cycle from 20 to 30 years to two to three years, This requires innovative breakthroughs in material corrosion research,利用模拟计算和数据交叉共享发展高效、可靠的腐蚀试验新方法、环境严酷性分级新标准、多尺度腐蚀行为新理论和寿命预测新模型。以钢铁大气腐蚀的监检测和评估为例,简要说明腐蚀试验测试与大数据评估技术的研究进展及其应用。

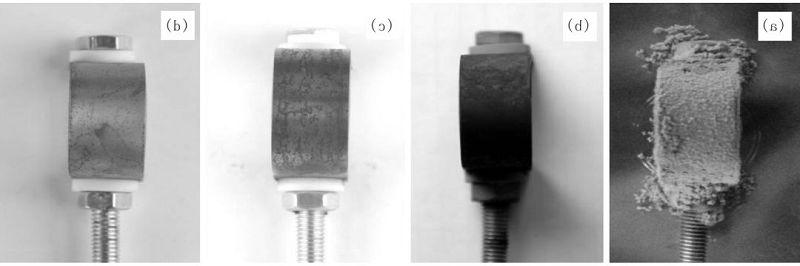

The corrosive damage of metal materials in the atmosphere is mainly caused by the alternation of wet and dry climates。其腐蚀过程是由于金属在薄层液膜下发生电化学腐蚀,因此,大气腐蚀过程既满足电化学腐蚀的一般规律, 又具有其自身的特点。当前,大气腐蚀监测( ACM )仪仍是研究大气腐蚀的重要工具,ACM 仪根据薄膜电化学电池的电流讯号反映大气环境腐蚀性强弱。其中,ACM 电池作为监测仪中的重要部分,是以腐蚀电化学原理中电偶腐蚀原理设计的。

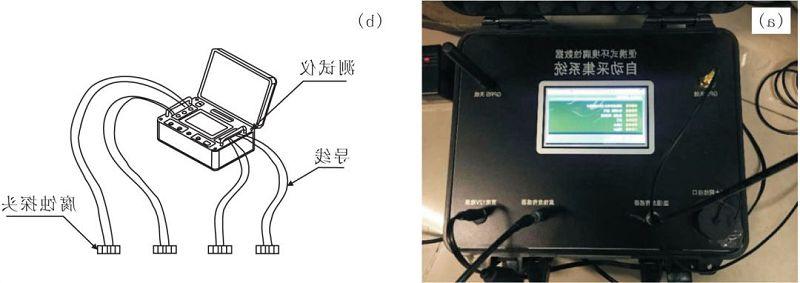

The author developed a multi-channel atmospheric environment corrosion monitoring equipment suitable for high-throughput data acquisition, as shown in Figure 5 。这种监测仪可以选取多个典型大气环境对不同空间和时间下钢铁材料腐蚀程度进行在线监测。大气腐蚀监探头通过测量薄液膜下电化学电池的电流讯号反映大气环境腐蚀性强弱, 根据给出的数据初步分析不同区域大气腐蚀的主要环境因子及其腐蚀环境特点。Atmospheric corrosion monitoring probe can be customized according to the monitored space and working conditions, especially suitable for monitoring the change trend of environmental corrosion degree。

Figure 5 ACM detection devices

The ACM device application system uses the B/S architecture and Java language,Support cross-platform operation,Support GIS map display,It can display and store the environment and climate in real time, Interface dynamic instrument graphical display of microclimate monitoring point data, The device also has the function of historical data query, chart output and analysis of monitoring points。

ACM monitoring technology based on Internet big data,The intelligent monitoring of corrosion big data is realized, 弥补了传统挂片实验设计周期长、数据碎片化、数据积累过程中多种环境因素耦合的不稳定性及数据监测滞后性等不足,Big data on corrosion environment (temperature, humidity, chloride ion concentration, SO2浓度、颗粒物含量等)的实时智能化自动采集,材料信息学高通量计算与分析,以及腐蚀过程实时智能化监测等功能,最终形成具有“腐蚀大数据”特质的钢铁材料服役数据共享平台。通过该平台, 实现了对钢铁材料服役过程中腐蚀数据的在线采集、数据分析、加工挖掘与信息管理,为实现钢铁材料及其构件安全健康诊断提供新方法,进一步发展了岛礁用钢的腐蚀防护技术 。

4 结语

Focus on the urgent needs of national economic construction and strategic layout, Continuous improvement of environmental corrosion test methods for steel materials under natural environment, 持续进行钢铁材料及制品在国内外典型自然环境及严酷、极端环境(深 / 远海、西 / 南沙、南 / 北极等)中腐蚀数据积累,Enrich and improve the environmental corrosion database of steel products;On the basis of multi-period, long series data,Further develop the integrated application and practice of information technology such as modeling, simulation and knowledge mining, 充分认识和揭示钢铁材料环境腐蚀科学规律和机理;完善钢铁材料的环境腐蚀评价标准体系, Make the natural environment corrosion test research work of domestic materials in line with international standards,To improve the quality of steel products,Enhance the international competitiveness of China's iron and steel to contribute。

|

Scan the QR code with your phone

- Business consulting

- Enquiry telephone 023-67787593

- Back to top

Service Hotline:

传真:023-67787596

网址:www.gwenlann.com

邮箱:info@gwenlann.com

Address: No.66 and No.180, Area c, Sendi Avenue, Jiulongpo District, Chongqing

Copyright © 2020 Chongqing Dayou Surface Technology Co., LTD All Right Reserved Chongqing ICP for 16005686

Copyright © 2020 Chongqing Dayou Surface Technology Co., LTD

Chongqing ICP for 16005686